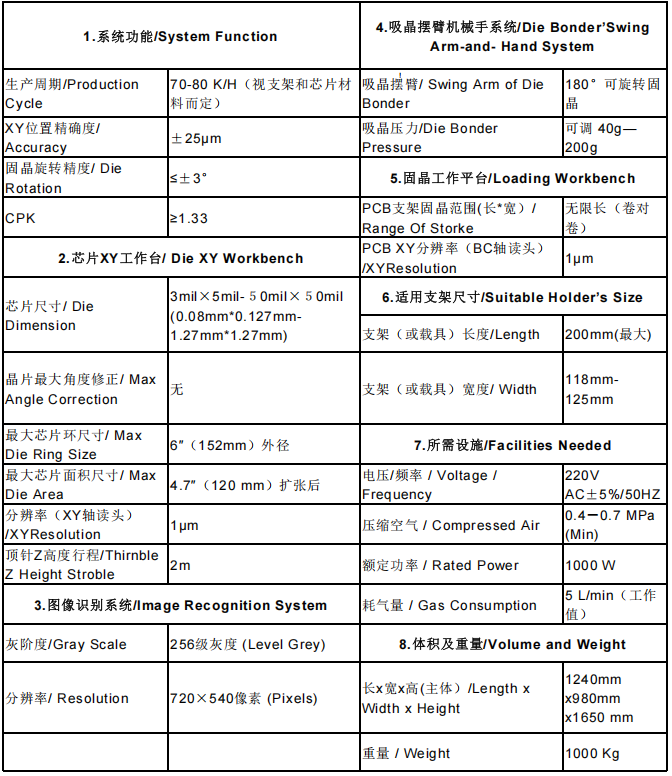

1、Advanced Bond Head Mechanism: Industry-leading bond head mechanism delivers exceptional bonding stability and consistency, virtually eliminating three-point deviation. Utilizes premium domestic/international brand power and core components for reliable operation and durability. Standard die bonding nozzles offer high cost-effectiveness with adjustable pick/bond pressure to accommodate diverse process requirements.

2、 High-Efficiency Feeding Platform: Precision-assembled with top-tier linear motors and guides. Meets high-speed, high-precision positioning demands while ensuring operational stability and extended service life—laying the foundation for efficient production.

3、Flexible Fixture Design: COB vacuum-adsorption fixtures feature adjustable width (118mm–125mm) to accommodate various product dimensions, enhancing equipment versatility and adaptability.

4、Innovative Feeding/Unloading Design: Simplified cylinder modules enable material handling by vertically clamping LED strips. Integrated sensors on buffer plates detect strip length in real-time, preventing tension damage during transfer and ensuring continuous production.

5、Premium Wafer Platform: Industry-leading platform built with top-tier linear motors and guides. Delivers high-speed, high-precision positioning with outstanding stability and longevity. Supports 6-inch single-wafer ring operations for diverse production needs.

6、Rapid-Changeover Module: Industry-unique integrated wafer ring/feeder module allows seamless switching. Changeover completed in ≤15 minutes, significantly boosting production flexibility and efficiency. Enables agile transitions between process modes for enhanced competitiveness.