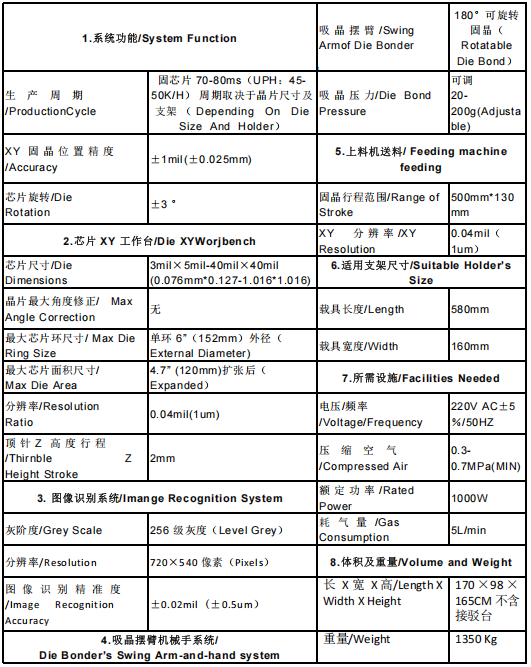

1、 Integrated Solder Dotting & Die Bonding: Supports PCB/LED panels up to 580×160mm with a maximum adsorption platform size of 510×148mm. Enables 500mm bonding in a single operation. Innovative simultaneous solder dotting and die bonding significantly enhances throughput. Dual-head solder dotting ensures uniform dot size without bridging, with precise volume control.

2、Self-Developed Technology & Stability: Features proprietary pick & bond heads and dual-dispensing structures. Solder dotting units incorporate precision heating and temperature control for consistent results. Real-time solder paste monitoring guarantees accuracy and stability. 90% structural components are domestically sourced, eliminating long lead times for replacements.

3、Precision Positioning System: Wafer and PCB platforms utilize linear motor drives with high-resolution magnetic encoder scales and optical positioning. Achieves accurate die locating and bonding alignment, improving yield and product quality.

4、Flexible Dual-Dispensing Structure: Independent standardized dispensing sleeves support single-arm + split-head modes. User-customizable operation simplifies workflows. Standardized consumables (dispensing heads/sleeves) reduce procurement costs.

5、Quick-Release Glue Tray: Patented threadless quick-release/install design streamlines maintenance. Minimizes cleaning time and equipment downtime, boosting overall productivity.

6、Automated Material Feeding: Dual front-side basket feeders enable automatic material loading. Reduces labor costs while enhancing automation efficiency and production throughput.

7、 Imported Precision Components: High-speed motion modules (THK, NB, CKD, SMC) ensure operational stability, extended service life, and reduced maintenance costs.

8、Robust Control System: Industrial PC + C++ control delivers advanced software functionality. Intuitive operation reduces errors and simplifies maintenance/upgrades.