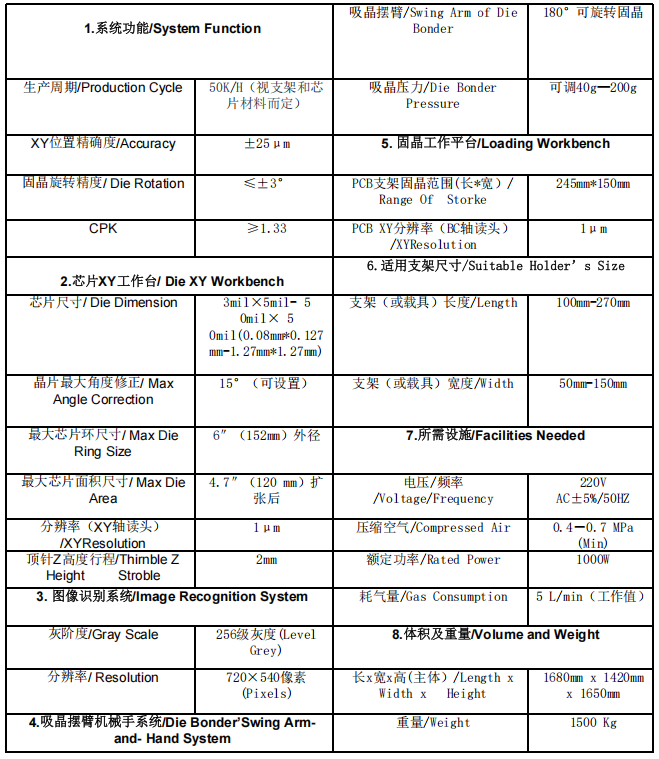

1、High-Efficiency Dual-Head Operation System: Equipped with dual feeding (BC fixture) platforms and a dual-side die bonding system. Enables simultaneous processing of two substrates (products), significantly exceeding the production capacity of similarly sized equipment in the industry. Delivers efficient output, saving customers time and costs.

2、Exceptional Dispensing System: Features an industry-leading dual dispensing system with outstanding performance. Effortlessly handles COB flip-chip die bonding tasks, providing robust assurance for high-quality die bonding.

3、High-Precision Dispensing Mechanism: As an industry-leading dual dispensing mechanism, it offers exceptional stability and consistency. Powered by top-tier domestic and international brand components for stable and durable operation. Uses universal consumables (dispensing heads, glue trays, scrapers) with high cost-effectiveness. Size-swappable glue trays effectively reduce adhesive consumption and lower production costs.

4、Advanced Bond Head Mechanism: Industry-leading bond head mechanism ensures excellent bonding stability and consistency, virtually eliminating three-point deviation issues. Utilizes premium domestic and international brand power and core components for reliable operation and longevity. Standard die bonding nozzles facilitate easy consumable procurement. Supports adjustable pick & bond pressure to meet diverse process requirements.

5、High-Speed Feeding Platform:Built with top-tier linear motors and guides from domestic/international brands. Precision-assembled into an industry-leading feeding platform that meets high-speed, high-precision positioning demands. Guaranteed stability and extended service life for smooth, efficient production.

6、 Large Bonding Stroke & Flexible Fixtures: Fixture bonding stroke: 245mm x 150mm—exceeding mainstream industry COB dual-head die bonders (220mm x 110mm). Dedicated fixtures for COB rigid substrates accommodate 90% of standard products. Eliminates the need for specialized backing plates or covers (jigs) when switching product sizes, enhancing versatility and convenience.

7、Premium Wafer Platform: Industry-leading wafer platform mechanism assembled with top-tier linear motors and guides. Delivers high-speed, high-precision positioning with exceptional stability and longevity. Supports 6-inch single-ring operation and features wafer ring die angle correction (adjustable up to 15°) to accommodate large-angle incoming chips, improving compatibility.

8、High-Efficiency Ejector Pin Mechanism: Industry-leading ejector pin mechanism with high precision and rapid response, accelerating and optimizing production efficiency.

9、Diverse Feeding/Unloading Modes: Flexible feeding/unloading options: Stack magazine feeding + tray unloading (standalone); Tray pushing feeding + tray unloading (standalone); Stack magazine feeding + unloading to conveyor (connects to belt line for oven or next process) ; Tray pushing feeding + unloading to conveyor (as above); Meets diverse production scenarios and process needs, enhancing operational flexibility.

10、Compact Design & User-Friendly Operation: Compact structure minimizes footprint for COB large-stroke dual-head equipment. Magnetic suction head design simplifies product switching and head position adjustment. Operator-friendly details (e.g., movable tray stoppers, high-capacity magazine storage) enable easy loading/unloading. Supports one operator managing multiple machines, reducing labor costs and boosting productivity.