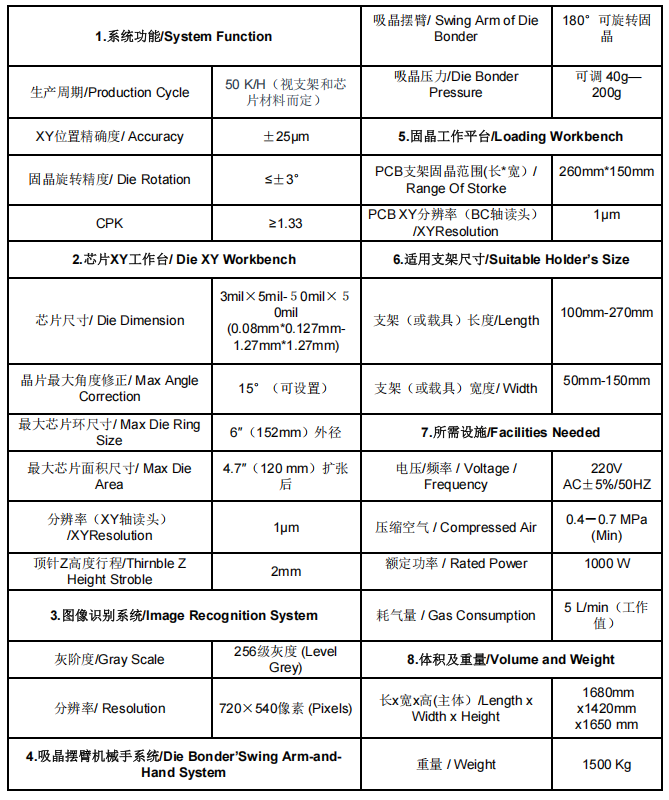

1、 High-Efficiency Dual Operation System: Equipped with dual feeding (BC fixture) platforms and a dual-side die bonding system. Enables simultaneous processing of two substrates (products). Significantly increases production capacity compared to similar-sized equipment in the industry, delivering high-efficiency output.

2、Exceptional Dispensing System: Features an industry-leading dual dispensing system tailored for COB flip-chip die bonding. Ensures smooth operation and lays the foundation for high-quality die bonding.

3、High-Precision Dispensing Mechanism: As an industry-leading dual dispensing mechanism, it offers outstanding stability and consistency. Powered by top-tier domestic and international brand components, ensuring stable and durable operation. Uses universal consumables (dispensing heads, glue trays, scrapers) with high cost-effectiveness. Glue trays are size-swappable, effectively reducing adhesive consumption.

4、Advanced Bond Head Mechanism: Industry-leading bond head mechanism delivers excellent bonding stability and consistency, virtually eliminating three-point deviation issues. Utilizes premium domestic and international brand power and core components for reliable operation and longevity. Standard die bonding nozzles facilitate easy consumable procurement. Supports adjustable pick & bond pressure.

5、High-Speed Feeding Platform: Built with top-tier linear motors and guides from domestic/international brands. Precision-assembled into an industry-leading feeding platform that meets high-speed, high-precision positioning requirements. Ensures stability and extended service life for smooth, efficient production.

6、Large Bonding Stroke & Flexible Fixtures: Fixture bonding stroke: 260mm x 150mm—exceeding mainstream industry COB dual-head die bonders (220mm x 110mm). Includes dedicated fixtures for COB rigid substrates, compatible with 90% of standard products. No need for specialized backing plates or covers (jigs) when switching product sizes, greatly improving versatility and convenience.

7、Premium Wafer Platform: Industry-leading wafer platform mechanism assembled with top-tier linear motors and guides. Delivers high-speed, high-precision positioning with exceptional stability and longevity. Supports 6-inch single-ring operation and features wafer ring die angle correction to accommodate large-angle incoming chips, enhancing compatibility.

8、High-Efficiency Ejector Pin Mechanism: Industry-leading ejector pin mechanism with high precision and rapid response, accelerating and optimizing the production process.

9、Diverse Feeding/Unloading Modes: Flexible feeding/unloading options: Stack magazine feeding + tray unloading (standalone); Tray pushing feeding + tray unloading (standalone); Stack magazine feeding + unloading to conveyor (connects to belt line for oven or next process); Tray pushing feeding + unloading to conveyor (as above); Meets diverse production scenarios and process needs, enhancing operational flexibility.

10、Compact Design & User-Friendly Operation: Compact structure minimizes footprint for COB large-stroke dual-head equipment. Magnetic suction head design simplifies product switching and head position adjustment. Operator-friendly details (e.g., movable tray stoppers, high-capacity magazine) enable easy loading/unloading. Supports one operator managing multiple machines, reducing labor costs and boosting efficiency.