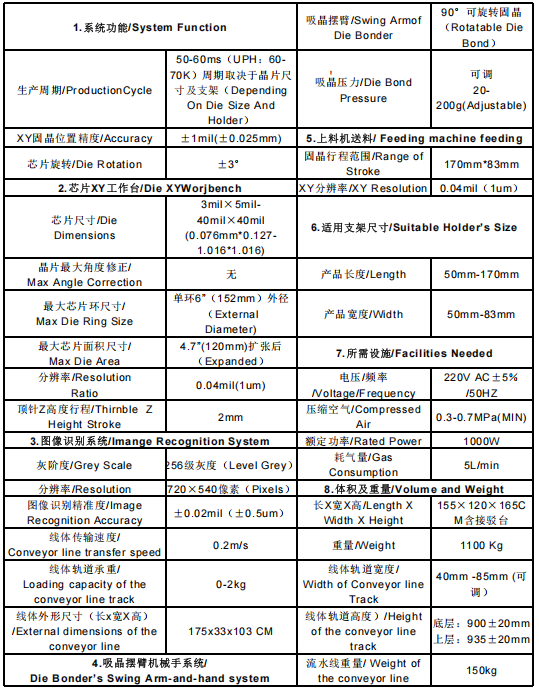

1、Premium Core Components: Critical components (guides, linear motors, stepper motors, encoder read heads) utilize top-tier domestic and international brands. All are standard parts with readily available inventory, ensuring short lead times and stable equipment operation.

2、Robust Bond Head Environmental Adaptability: Bond heads maintain optimal performance under extreme high/low temperature conditions. Ensures consistent stability and reliability in harsh operating environments.

3、Precision Wafer Positioning: Combines linear motor drives, high-resolution magnetic/optical encoder scales, and an optical positioning system. Achieves accurate die locating and bonding positioning, enhancing production efficiency and product quality.

4、High-Efficiency Ejector Pin Mechanism: Unique structural design enables rapid and precise piercing of blue film by ejector pins. Guarantees efficient and stable die bonding processes.

5、Dual-Layer Conveyor for Enhanced Efficiency: Dual-layer conveyor design enables top/bottom switching for feeding/unloading die bonder fixtures. Utilizes belt-driven material handling with minimal motion, short transfer times, and secure product retention on the line, significantly improving throughput.

6、Compact & Flexible Buffer Conveyor: Space-saving buffer conveyor structure caches both non-bonded and bonded products. Maximizes die bonding efficiency through intelligent material flow management.

7、Optimized Material Handling Efficiency: Dual-layer conveyor design: Top layer feeds from upstream processes (e.g., SPI), bottom layer outputs bonded products directly to downstream processes (e.g., reflow soldering). Segregated flow paths prevent material mixing and maximize transfer efficiency.

8、Comprehensive Feeding/Unloading Functions: Feeding/unloading section features dual-layer conveyor design: Top layer supplies upstream materials or feeds buffer conveyors; bottom layer unloads bonded products to buffer conveyors or transfers materials. Inherits all advantages of integrated feeding/unloading systems.