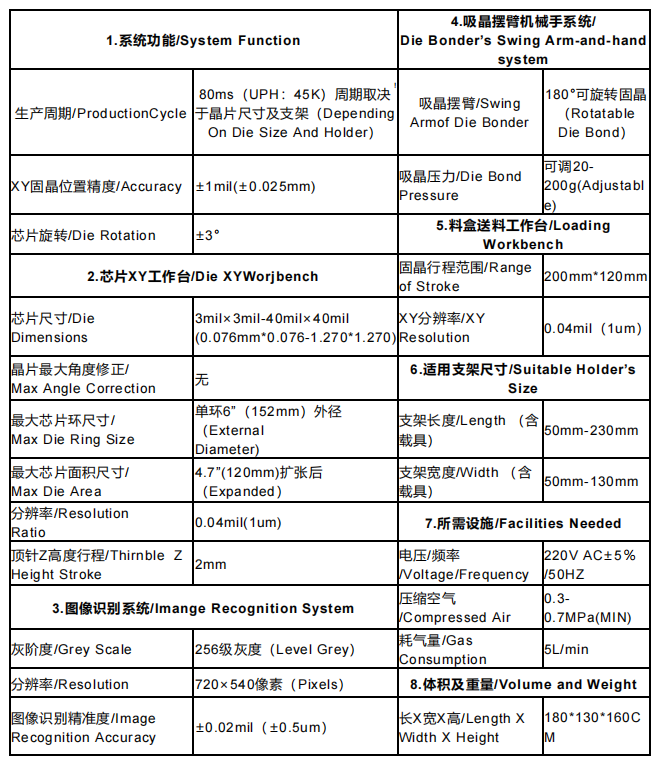

1、High-Efficiency Integrated Operation: Supports PCB/LED panels up to 250mm (L) x 150mm (W). Equipped with dual loading/unloading stations and conveyors, enabling simultaneous solder dotting and die bonding, significantly improving die bonding efficiency. The dual-head solder dotting mechanism ensures uniform dot size without bridging, with precise solder volume control.

2、Self-Developed & Stable Performance:Features self-developed pick & bond heads and dual dispensing structures, guaranteeing equipment precision and stability. 90% of structural components are locally sourced, effectively avoiding long lead times for replacement parts and ensuring production continuity.

3、Precise Positioning System:Utilizes linear motor drives and high-resolution magnetic encoder scales for the Wafer and PCB platforms, combined with an optical positioning system. Achieves precise positioning for die finding and bonding, improving production efficiency, product quality, and reducing defect rates.

4、Flexible Dual-Dispensing Structure:The dual dispensing structure employs independent, standardized dispensing sleeves, supporting a single-arm and split dispensing head mode. Customers can freely configure the usage method according to their needs; Operation is simple and fast. Standard dispensing heads and sleeves facilitate easy market procurement of consumables, lowering operating costs.

5、 Convenient Glue Tray Structure:Employs a self-developed thread-less quick-release and quick-installation method for glue trays. Easy to operate, improves cleaning efficiency for operators, reduces equipment downtime, and enhances overall production efficiency.

6、Automated Feeding Design:Dual front-side basket feeders enable automatic material pushing, reducing labor costs, increasing production automation, helping lower production costs, and improving efficiency.

7、Imported Precision Components Ensure Quality: High-speed precision motion components utilize imported brands like THK, NB, CKD, SMC, etc., which ensuring stable machine operation, extending equipment lifespan, reducing maintenance costs, and providing reliable hardware support for production.

8、Powerful Control System: Operates using an Industrial PC + C++ program control, featuring robust software capabilities. Simplifies equipment operation procedures, making it easy and convenient to use, reducing operational difficulty and error rates, increasing production efficiency, and facilitating maintenance and upgrades.